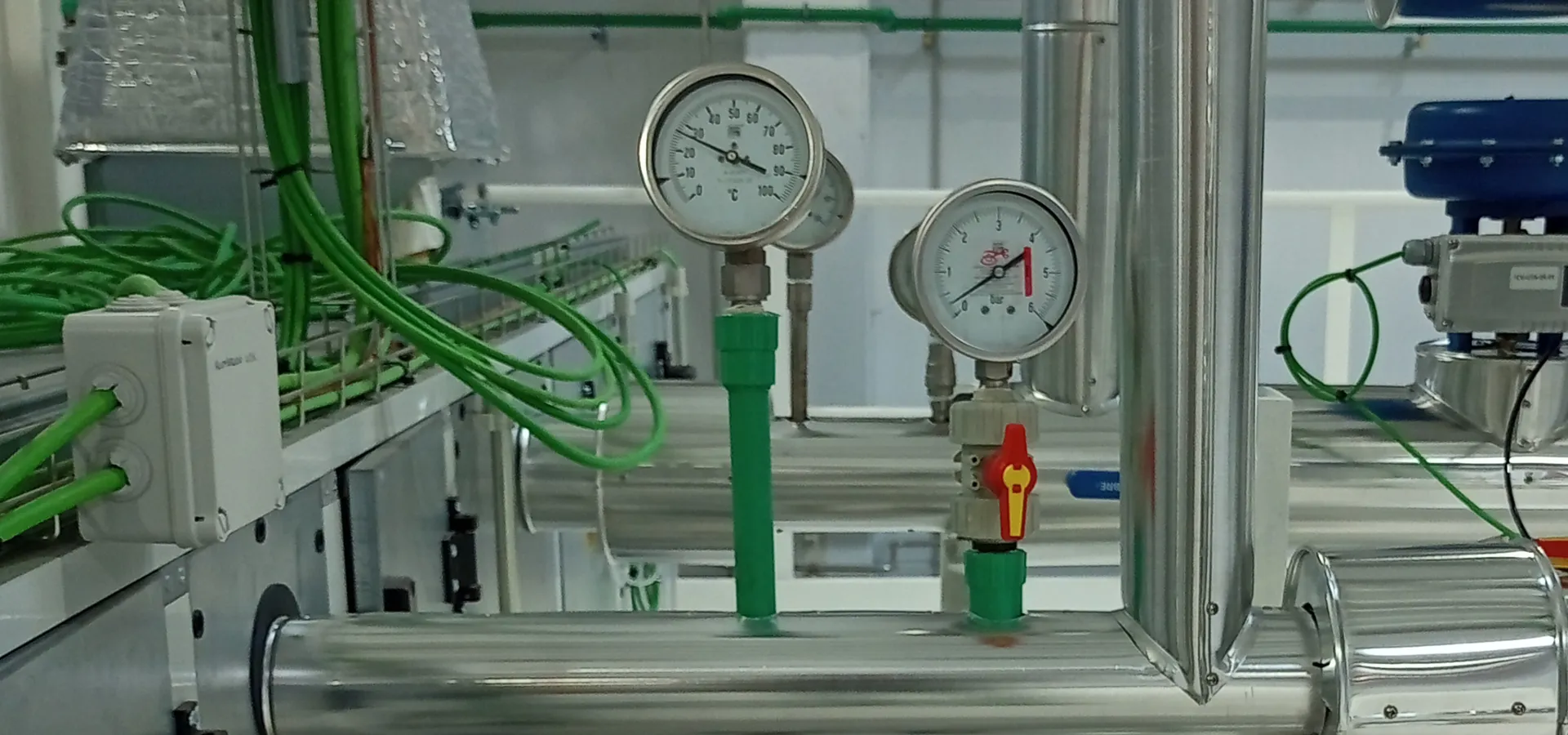

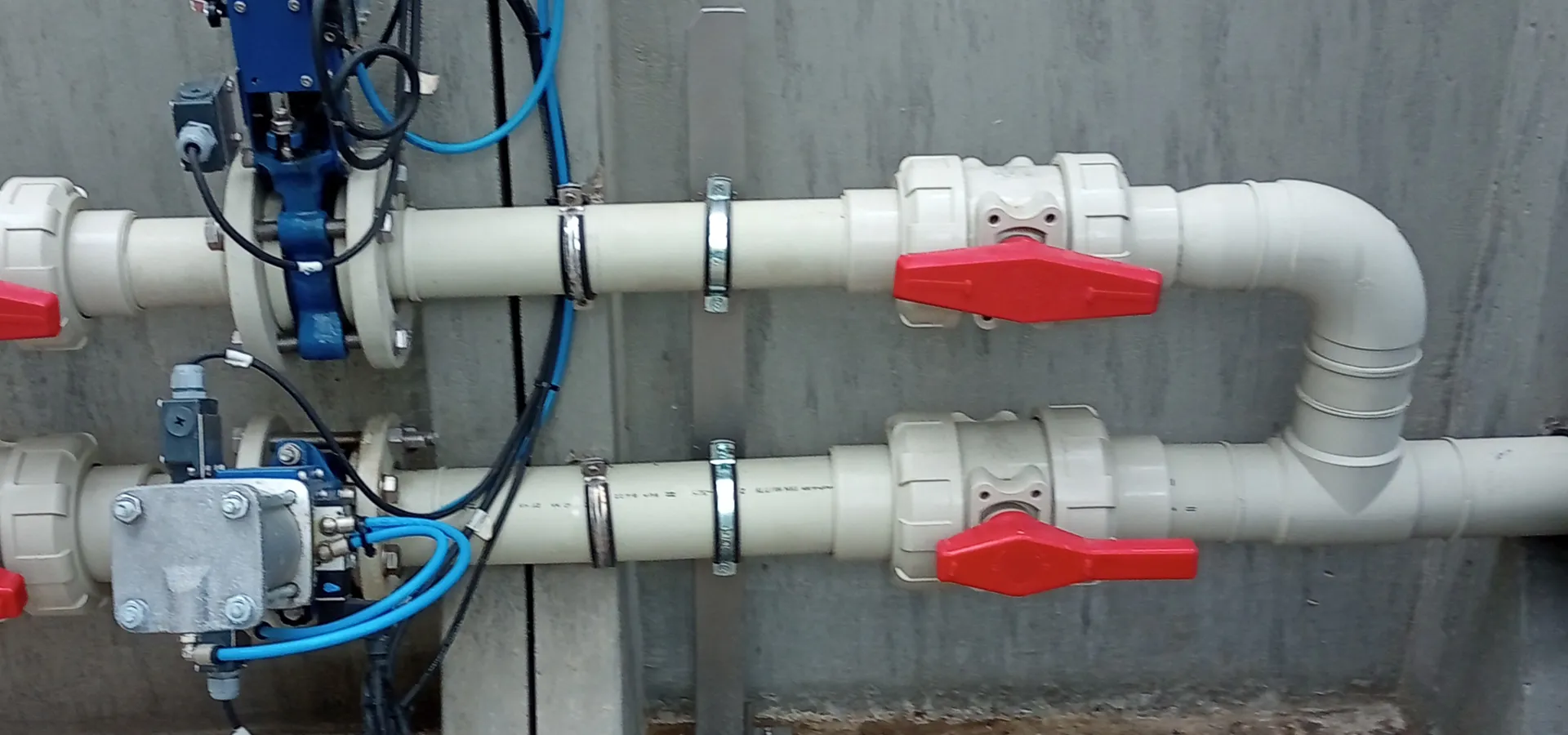

MPLR has personnel with extensive experience in the installation of ducts in technical plastics, as well as all control elements (pumps, valves, flow meters, etc.), capable of performing assemblies from corrosive acids to ultra-pure water.

The company has state-of-the-art welding machinery and certified personnel for these tasks.

Types of Welding:

- Electrofusion accessory welding (PE and PP)

- Butt welding (PE, PP, and PVDF)

- Cold chemical welding (PVC, PVCC, and FRP)

- Socket or plug welding (PE, PP)

- Thermal material addition welding (PE, PVC, PP, and PVDF)

- Conveyance of Corrosive Liquids

- Installation and supply of conduits for the transfer of corrosive liquids:

- Materials: PVC, PVC-C, PPH, PEHD, PVDF, and FRP.

- Fluid control equipment, tanks, and special anti-corrosive pumping systems.

Drinking Water and Irrigation Conveyance Installation and supply of pipelines for the conveyance of drinking water: Materials: PVC and PEHD. Fluid control equipment and pumping systems for drinking water.

Deodorization Conveyance Conduits for gases, deodorization, and ventilation. Materials: PP, PPs, PPs-EL, FRP, Stainless Steel, and galvanized.

Tanks and Cisterns Manufacture and installation of reactors, settling tanks, pits, and tanks in thermoplastics such as PVC, PP, PEHD, PVC-C, PVDF, and FRP.